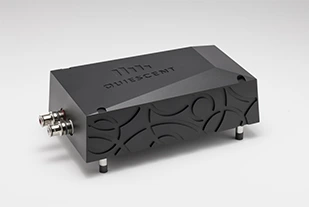

Apex Component Couplers

“If you want to hear what your system is really capable of I recommend giving them a try, and remember, in this case bigger is better.“

Jason KennedyJuly 2023

Performance

Astounding critics and customers, Quiescent’s couplers work by draining high-frequency noise and mechanical vibration from your system’s chassis resulting in improved musical agility, dynamics and realism. Deployed in sets of three per audio separate, the improvements are significant across the entire frequency spectrum without compromising the musical signal.

Technology

Perfectly Imperfect

When we invented the Vertex Kinabalu, we knew that one of the critical areas where audio equipment can be improved is draining mechanical vibration and EMI/RFI from the chassis.

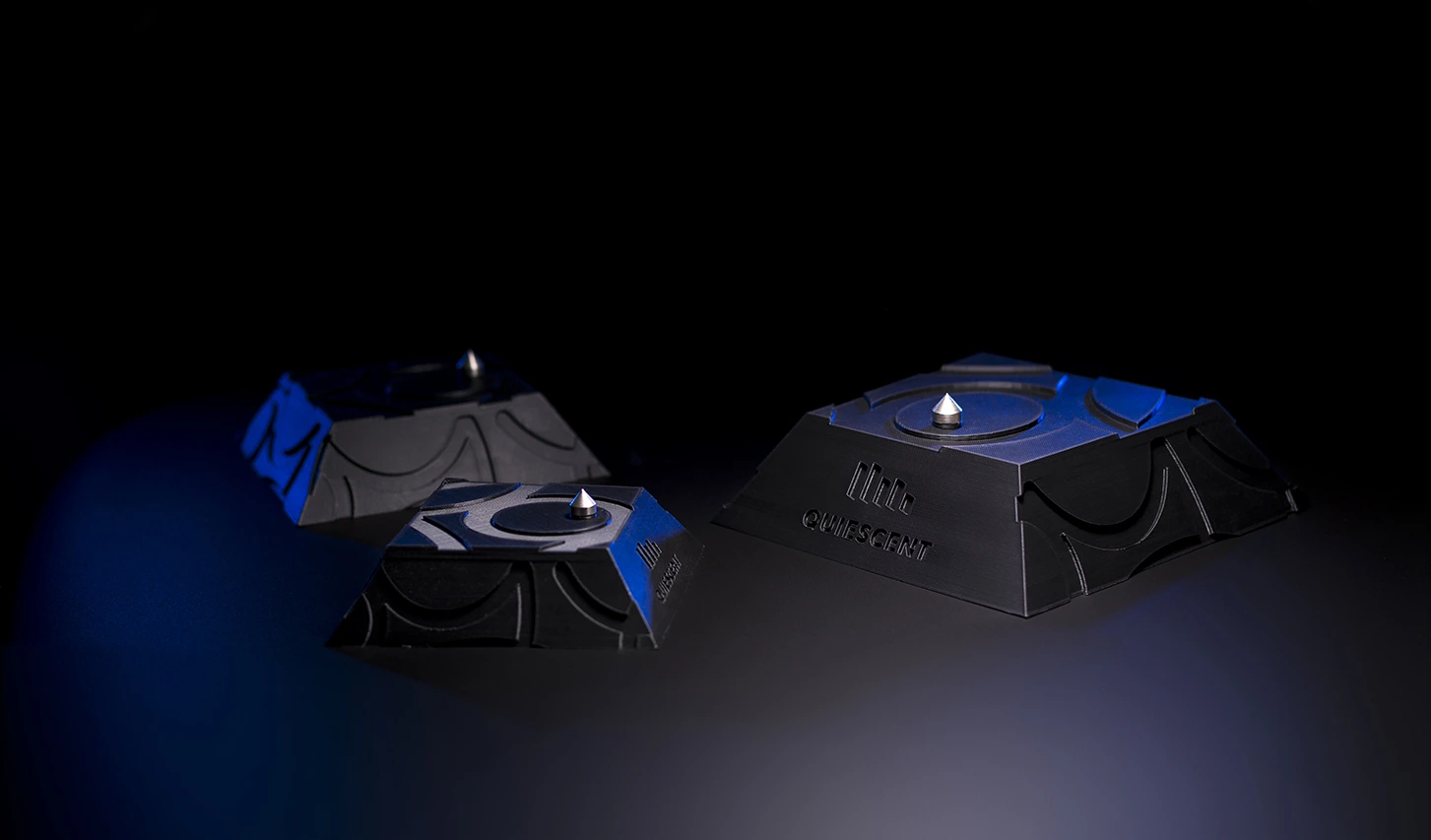

The problem with the Kinabalu and other equipment isolators is that uniform or regular shapes, whilst striking in appearance, actually lead to the re-emission of this damaging energy back into the equipment. The Apex couplers are deliberately designed to be irregular in shape and form, allowing wide-band return loss to increase significantly. This is why they are so effective across the entire musical spectrum.

Specifications

Component Couplers are available in three different configurations, Apex40, Apex50 and Apex60. The Apex40 is the smallest coupler, standing at 40mm high. The Apex60, at 60mm high, is the ultimate in equipment grounding capable of supporting the heaviest components such as power supplies and large amplifiers.

Technology

Most equipment isolation platforms and component isolators are designed to prevent unwanted vibration from being transmitted into your equipment. Conventional solutions are regular shapes such as cylinders, cones or cubes with uniform sides and often polished surfaces. Although simple to produce and attractive, these shapes have an inherently resonant acoustic behaviour. They also do not solve the real issue of what causes the loss of musical information. That is, airborne vibration is less significant than the high-frequency vibration caused by electronic component resonance and circulating eddy currents induced by electromagnetic fields in the equipment.

Our Vertex Kinabalu platforms were our first attempt at solving the problem of providing a path for these damaging forms of energy to be led away and dispersed. Like other solutions, the Kinabalu had uniform and familiar forms, making it an ideal platform that won many awards and plaudits. Our work with Kaiser Acoustics in creating the Leading Edge product range took this further by providing an improved path into our irregular and non-uniform labyrinth inside the platform.

We knew that the appliance of high-frequency engineering was the key to improving performance. We also suspected that a solution in closer proximity to the equipment was needed, which is why the Vertex couplers for the Kinabalu and Leading Edge range were upgraded to include vibrational and EMI/RFI absorption technology, albeit in a small package.

Through our research, we developed our patented approach used in the Apex couplers and other components in our range to find the ultimate goal of a wide-band, multi-phase device that exhibits a high return loss over multiple frequencies. This research has led to absorption labyrinths that are far more effective than our Kinabalu platforms and Leading Edge products, allowing us to place the needed technology directly inside the couplers and closer to the electronics.

The Apex coupler has non-parallel sides and disruptive surfaces that eliminate these problematic sonic characteristics. We use 3D printing techniques to ensure we have a structure which is deliberately perfectly imperfect. By having non-linear sides, a honeycomb structure and irregular shapes and patterns on the surface, the Apex provides an irregular path for vibration transmission, leading to phase and anti-phase cancellation that has never been previously achieved.

A low acoustic impedance spike is connected directly to a disruptive internal absorption matrix that provides a highly effective acoustic drain. This spike is formed from the hardest stainless steel available to ensure that it couples electrically with the component chassis. The other end of the spike is directly coupled to a proprietary wide-band, multi-phase filter. This arrangement, combined with our patented EMI/RFI technology, drains unwanted RFI from the electronic component, which is safely dissipated inside the coupler. Because of the Apex’s exceptionally high return loss, the reflection of this high-frequency vibrational and electrical energy back into the equipment is minimised.

Reduction in the chassis noise floor and component ground is considerable and substantially increases performance throughout the frequency spectrum. Once used, there are significant improvements in timing, bass, separation of instruments and vocals, image placement and transparency throughout the entire frequency range.

Your electronics are capable of much more than you have experienced. Try the Apex range of couplers to unlock their true potential.

Specifications

EMI/RFI Absorption Factor

1.00

W x D x H (mm)

121x110x40

Weight per Coupler (g)

400

Maximum Load Bearing (kg)

45

EMI/RFI Absorption Factor

2.01

W x D x H (mm)

151x138x50

Weight per Coupler (g)

783

Maximum Load Bearing (kg)

65

EMI/RFI Absorption Factor

3.78

W x D x H (mm)

194x165x60

Weight per Coupler (g)

1,444

Maximum Load Bearing (kg)

85