Apex Component Couplers

“If you want to hear what your system is really capable of I recommend giving them a try, and remember, in this case bigger is better.“

Jason KennedyJuly 2023

Performance

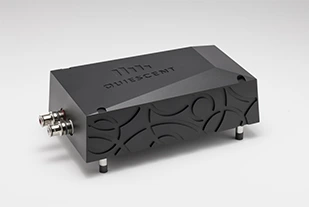

Astounding critics and customers, Quiescent’s couplers work by draining high-frequency noise and mechanical vibration from your system’s chassis resulting in improved musical agility, dynamics and realism. Deployed in sets of three per audio separate, the improvements are significant across the entire frequency spectrum without compromising the musical signal.

Technology

The Apex family of couplers takes a fundamentally different approach to noise. Rather than merely suppressing interference, our patented architecture provides a controlled escape path for internally generated high-frequency energy and vibration—quietly removing them from the system’s shared ground. The result is a calmer electrical environment and a musical performance revealed with greater purity and emotional impact

Specifications

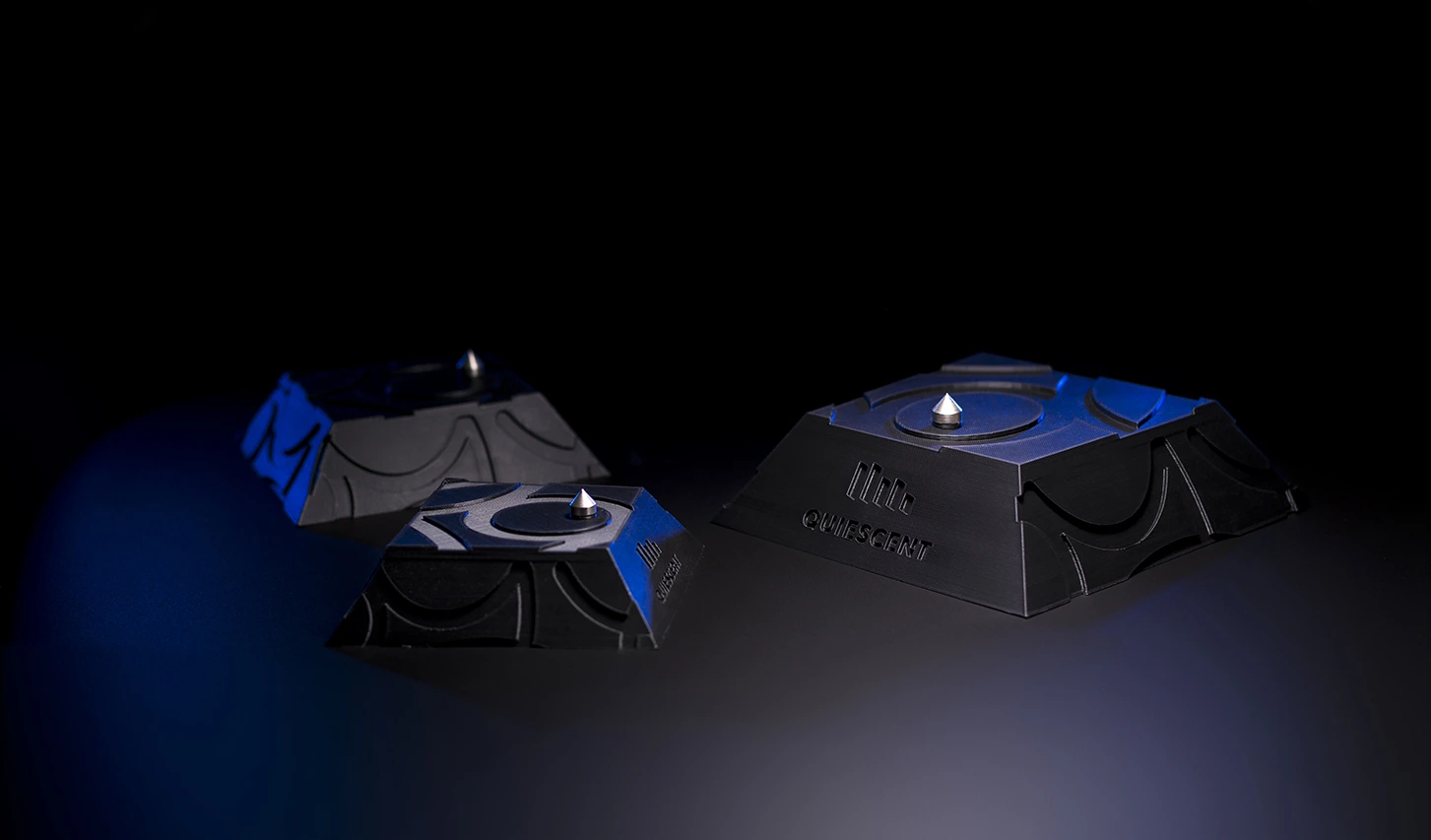

Component Couplers are available in three different configurations, Apex40, Apex50 and Apex60. The Apex40 is the smallest coupler, standing at 40mm high. The Apex60, at 60mm high, is the ultimate in equipment grounding capable of supporting the heaviest components such as power supplies and large amplifiers.

Technology

Most equipment isolation platforms and component isolators are designed with a singular objective: to prevent external vibration from entering the equipment. These solutions typically employ regular geometries—cylinders, cones, cubes—with uniform faces and polished surfaces. While visually appealing and straightforward to manufacture, such forms exhibit predictable and often pronounced resonant behaviour. More critically, they address only a secondary aspect of the problem.

Our research demonstrated that airborne vibration is rarely the primary cause of musical information loss. Instead, the dominant contributors are internally generated high-frequency vibration arising from electronic component resonance, together with circulating eddy currents induced by electromagnetic fields within the chassis. These mechanisms operate across a broad frequency range and interact directly with the system ground, where their effects accumulate.

In response, Quiescent developed a patented approach—implemented in the Apex couplers and across our wider range—with a clearly defined objective: the creation of a wide-band, multi-phase device exhibiting consistently high return loss over multiple frequencies. This goal required moving beyond conventional geometries and addressing both mechanical and electrical energy simultaneously.

During development, we observed that regular metal shapes reliably alter the sonic character of audio components. However, controlled evaluation revealed that these changes were frequency-dependent and inconsistent—often benefiting one region of the spectrum at the expense of another. This reinforced our conclusion that such devices modify system behaviour without resolving the underlying mechanisms responsible for degradation.

The Apex coupler is engineered explicitly to avoid these limitations. Its non-parallel faces and deliberately disruptive surfaces eliminate the coherent resonances inherent in regular forms. Advanced 3D-printing techniques are employed to realise a structure that is intentionally non-uniform: a complex honeycomb interior combined with irregular external geometries. This creates an unpredictable transmission path for vibration, promoting phase and anti-phase cancellation across a broad frequency range.

A low-acoustic-impedance spike interfaces directly with the component chassis and couples into an internal absorption matrix designed to act as an efficient acoustic drain. Manufactured from exceptionally hard stainless steel, the spike also ensures effective electrical coupling. At its termination, energy is transferred into a proprietary wide-band, multi-phase filter that, working in concert with our patented EMI/RFI technology, dissipates unwanted high-frequency electrical noise safely within the coupler itself. The Apex’s exceptionally high return loss minimises the reflection of both vibrational and electrical energy back into the equipment.

The result is a substantial reduction in chassis-borne noise and ground contamination, yielding measurable improvements in system stability and performance across the entire frequency spectrum. Temporal accuracy improves, bass gains authority without overhang, spatial separation becomes more precise, and transparency increases without tonal imbalance.

Your electronics are capable of far greater performance than is typically realised. The Apex range of couplers is engineered to reveal it through science, not conjecture.

Specifications

EMI/RFI Absorption Factor

1.00

W x D x H (mm)

121x110x40

Weight per Coupler (g)

400

Maximum Load Bearing (kg)

45

EMI/RFI Absorption Factor

2.01

W x D x H (mm)

151x138x50

Weight per Coupler (g)

783

Maximum Load Bearing (kg)

65

EMI/RFI Absorption Factor

3.78

W x D x H (mm)

194x165x60

Weight per Coupler (g)

1,444

Maximum Load Bearing (kg)

85